In response to a further request from our clients ¬ whether we were able to build a Ring Insert System with even larger ring storage ¬ we could not help but answer “YES.“

Within a very short time, we constructed a system with two ring magazines with 24 spindles each. Each magazine offers storage for 1500 rings and the system itself for 3000 rings! This enormous buffer ensures the system only needs to be loaded once a day.

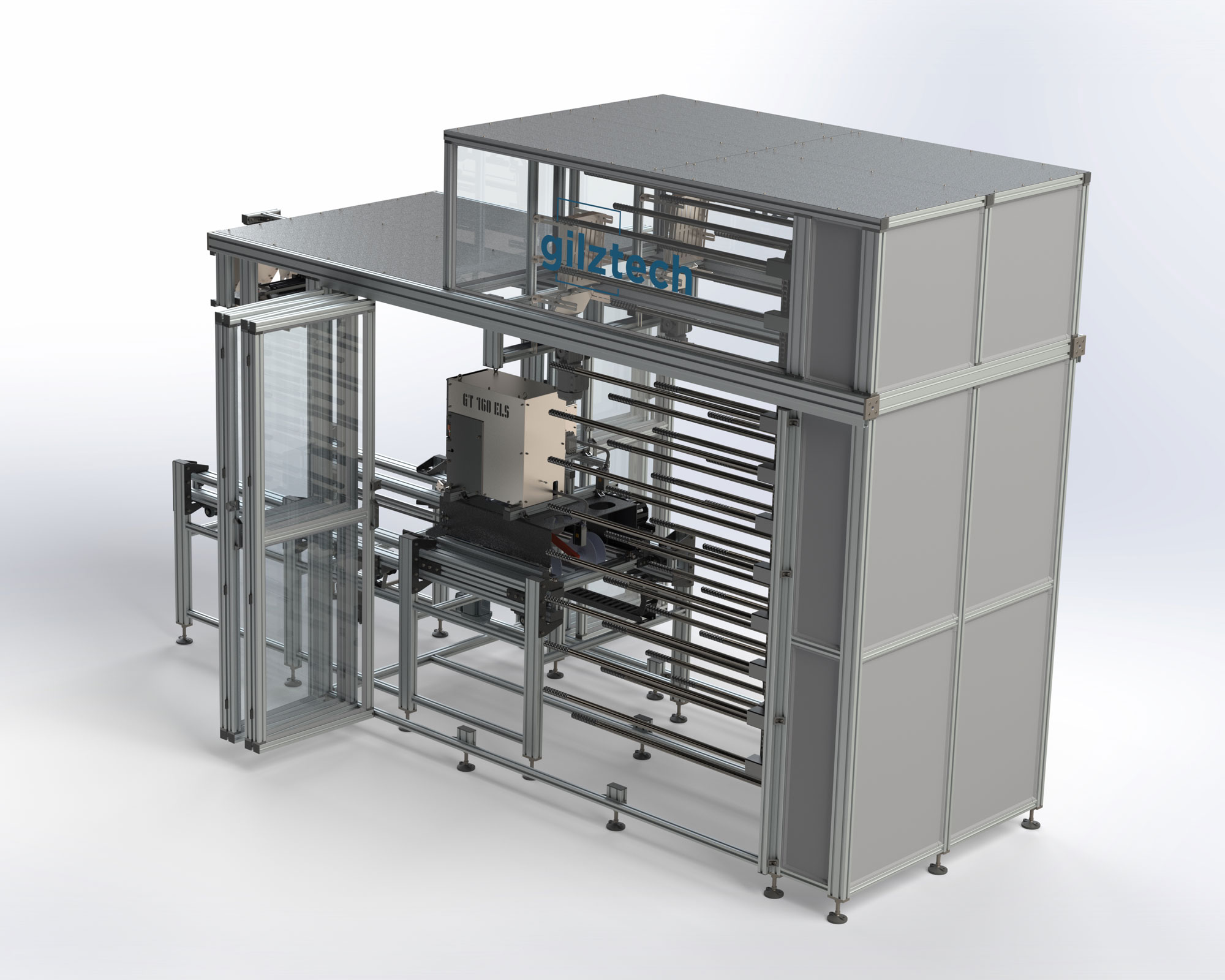

As with every Ring Insert System from Gilz Tech GmbH, we set great value on a compact and functional design. The ring inserters themselves are maintenance-free. In addition, all our assemblies are modular and can be removed and installed in only a few simple steps.

Very special about the system is the front area: It is placed in a safety fence area where the staff cannot enter without the machine stopping itself automatically. For this reason, we also developed a traversing unit for our ring inserter and the labeler. It can move them into an accessible area for the operator. The staff can now refill the labeler at a comfortable working height. Another special feature of our system is the conveyer for the ring inserter. It can be switched so that the rings are transported from the ring magazine to the opposite ring inserter. Another special feature of our system is the conveyer for the ring inserter. It can be switched so that the rings are transported from the ring magazine to the opposite ring inserter.

- Maintenance-free Ring Insert System

- Extremely large ring magazine

- No pre-treatment of the sealing rings

- Traversing unit for the ring inserter and labeler

- Modular design system

- Lightweight aluminum frame construction

- Individual extension possibilities

- Compact and functional design